What is Remote Terminal Unit?

A Remote Terminal Unit (RTU) is a device used in industrial control systems to monitor and control various devices and processes remotely.

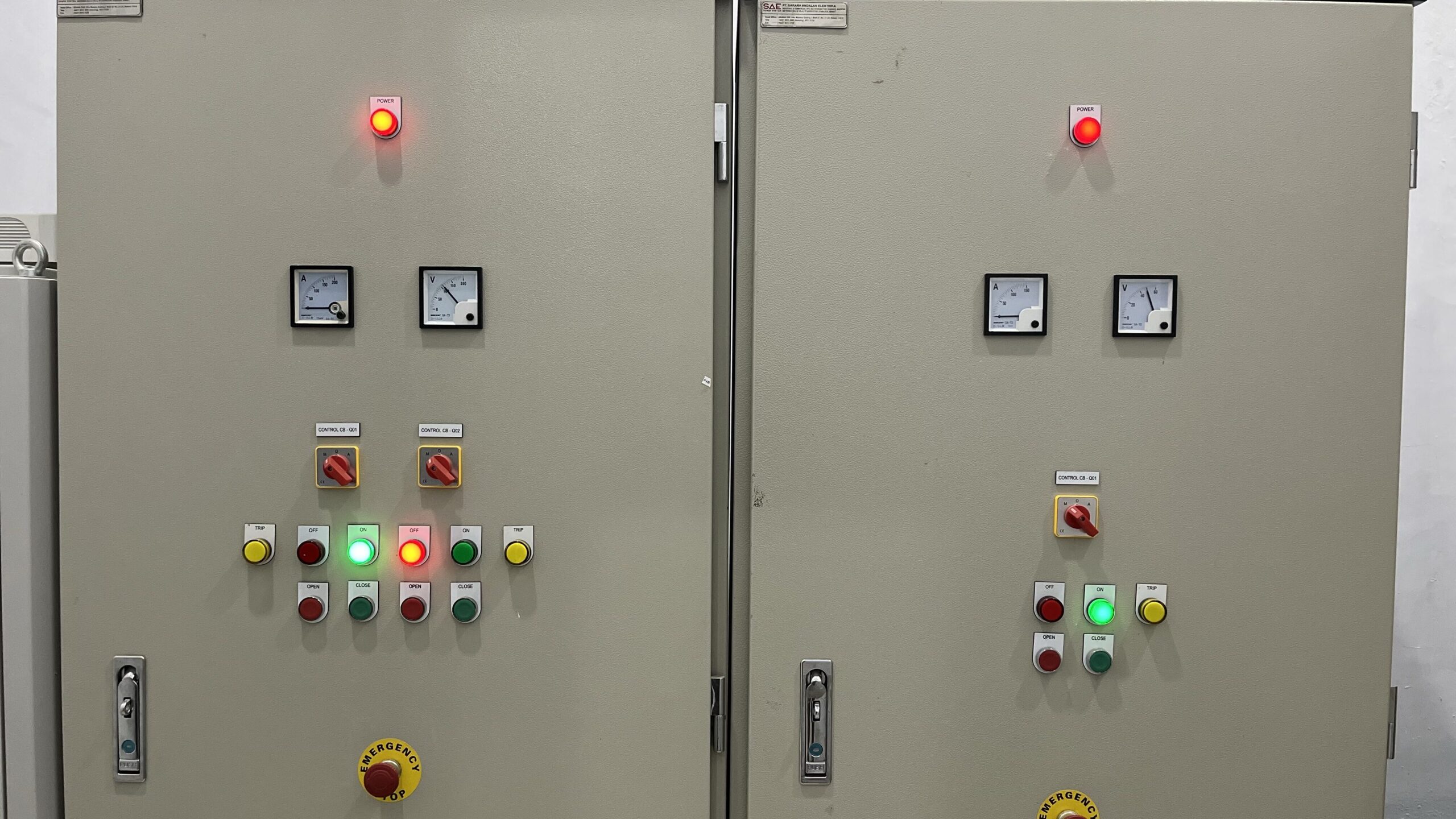

Remote Terminal Unit Definition: The RTU is typically installed in a remote location and connected to various sensors and actuators that are used to monitor and control physical processes, such as temperature, pressure, flow rate, or valve position.

The RTU collects data from these sensors and sends it to a central control system, where it is analyzed and used to make decisions about how to control the process.

RTUs typically includes a microprocessor, memory, input/output (I/O) modules, and communication interfaces. The communication interfaces allow the RTU to communicate with other devices, such as programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems, over various communication protocols, such as Modbus or DNP3.

The RTU’s ability to monitor and control devices remotely makes it a critical component of many industrial control systems, such as power generation, oil and gas pipelines, water treatment plants, and manufacturing facilities. By enabling remote monitoring and control, RTUs help to improve efficiency, increase safety, and reduce downtime and maintenance costs. You can continue to learn about Energy Management Systems.

Why do we use Remote Terminal Unit?

We use RTU remote terminal unit for several reasons:

- Remote monitoring: RTUs are used to monitor remote devices and processes that are located in distant or inaccessible areas, such as pipelines, wind turbines, or water treatment plants. By collecting data from sensors and transmitting it to a central control system, RTUs enable real-time monitoring of remote processes, ensuring that operators can respond quickly to any problems that may arise.

- Control: RTUs allows operators to remotely control various devices and processes, such as turning pumps on or off, adjusting valve positions, or changing setpoints. This enables operators to optimize the performance of industrial processes, minimize downtime, and reduce energy consumption.

- Communication: RTUs facilitate communication between different devices and systems in an industrial control network, such as programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems, and other RTUs. This enables different devices to work together, share data, and perform coordinated actions.

- Data acquisition: RTUs collect data from sensors and other devices, such as flow meters, pressure gauges, and temperature sensors, and transmit it to a central control system. This data is used for real-time monitoring, process optimization, and long-term analysis and planning.

How do Remote Terminal Unit Acquire Data?

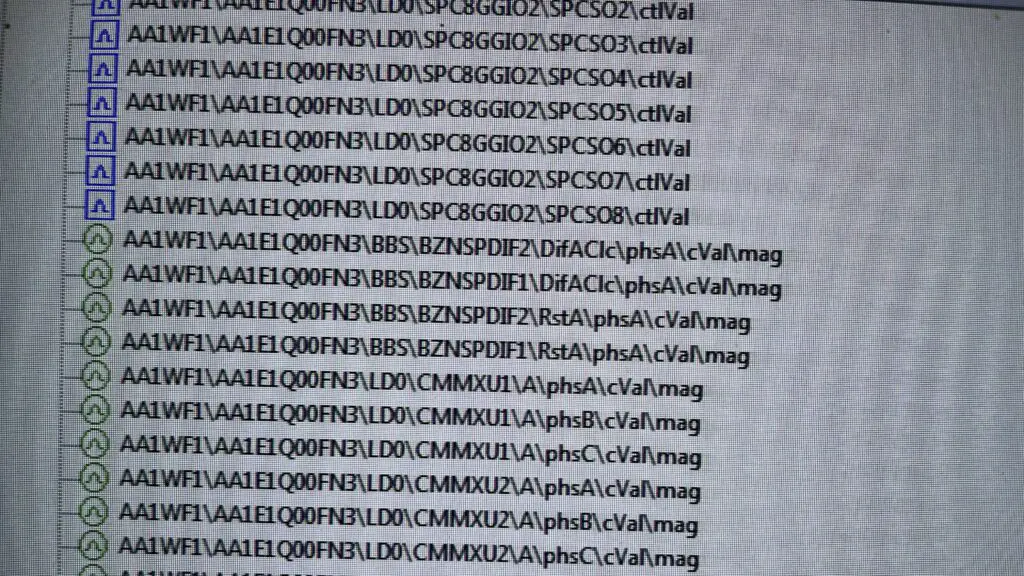

Remote Terminal Units (RTUs) acquire data from various sources in an industrial control system using different types of input channels. Some of the common ways RTU acquires data are:

- Analog Inputs: RTUs can acquire analog signals such as temperature, pressure, level, and flow using analog input channels. The input channels convert the analog signals into digital signals that the RTU can process and transmit to other devices in the control system.

- Digital Inputs: RTUs can acquire digital signals such as switch closures, contact closures, and pulse counts using digital input channels. These signals are typically used to monitor the state of various devices and processes in the control system.

- Serial Inputs: RTUs can acquire data from serial devices such as sensors, meters, and controllers using serial input channels. The RTU communicates with these devices using a communication protocol such as Modbus, DNP3, or IEC 60870-5.

- Ethernet Inputs: RTUs can acquire data from devices connected to Ethernet networks using Ethernet input channels. These devices can include sensors, meters, controllers, and other RTUs.

Once the RTU acquires data from these input channels, it processes the data and transmits it to other devices in the control system using communication protocols such as Modbus, DNP3, or IEC 60870-5. The RTU can also store the data in its memory for later retrieval and analysis.

Remote Terminal Unit Communication Protocols

Remote Terminal Units (RTUs) use various communication protocols to exchange data with other devices in an industrial control system. Some common RTU communication protocols include:

Read Also: IEC 101 vs. IEC 104: Understanding the Differences

- Modbus: Modbus is a serial communication protocol that is widely used in industrial control systems. It is a simple and robust protocol that supports both point-to-point and multi-drop communication.

- DNP3: DNP3 (Distributed Network Protocol) is a communication protocol that is specifically designed for use in the electric utility industry. It supports both serial and Ethernet communication and is capable of handling large amounts of data.

- IEC 60870-5: IEC 60870-5 is a series of communication protocols that are widely used in the power generation and distribution industries. It supports both serial and Ethernet communication and is designed to enable communication between different devices and systems in a power grid.

- Profibus: Profibus is a widely used industrial communication protocol that is used to connect devices in a variety of applications, including manufacturing, process control, and building automation. It supports both point-to-point and multi-drop communication and is capable of handling large amounts of data.

- Modbus TCP: Modbus TCP is a version of the Modbus protocol that uses TCP/IP for communication. It is commonly used in industrial Ethernet networks and enables devices to communicate over long distances.

These are just a few examples of the many RTU communication protocols that are available. The choice of the protocol will depend on the specific requirements of the industrial control system, such as the type of devices being connected, the distance between devices, and the amount of data that needs to be exchanged.

Modular Remote Terminal Unit

A Modular Remote Terminal (MRTU) is a type of Remote Terminal Unit (RTU) that is designed with a modular architecture. An MRTU consists of a base unit and one or more plug-in modules that can be added or removed as needed.

The base unit of an MRTU typically includes the central processing unit, power supply, and communication interface. The plug-in modules provide additional input/output channels and functionality such as analog and digital inputs, serial ports, and communication interfaces for different protocols.

The modular architecture of an MRTU provides several advantages, including:

- Flexibility: MRTUs can be customized to fit the specific needs of a particular application. Additional input/output channels or functionality can be added as needed without requiring the purchase of a completely new unit.

- Scalability: MRTUs can be scaled up or down depending on the size and complexity of the application. Additional modules can be added to accommodate new devices or expansion of the system.

- Upgradability: As technology evolves, new plug-in modules can be added to keep the MRTU up-to-date with the latest standards and protocols.

- Reduced Cost: The modular architecture of an MRTU reduces the cost of ownership and maintenance. Instead of purchasing a completely new unit, only the necessary modules need to be added or replaced.

- MRTUs are commonly used in industrial control and automation systems where flexibility, scalability, and upgradability are important. They can be found in applications such as power generation, oil and gas, water and wastewater, and transportation.

Overall, RTUs are essential components of industrial control systems, enabling remote monitoring and control of processes, facilitating communication between different devices and systems, and providing real-time data for analysis and optimization.

You must be logged in to post a comment.